| Availability: | |

|---|---|

| Quantity: | |

34CrNiMo6

Qilu

Product Description

DIN 34CrNiMo6 Qt Alloy Steel Round Bar

1: 34CrNiMo6 Steel Introduction

34CrNiMo6 Steel is an important alloy engineering steel grade as per BS EN 10083-3:2006. 34CrNim06 steel has high strength, high toughness and good hardenability. EN / DIN 34CrNiMo6 alloy steel has the stability of resistance to overheating, but the white sensitivity of 34CrNiM06 is high. It also has the temper brittleness, so the weldability of 34CrNiMo6 material is poor. The steel 34CrNiMo6 needs the high temperature preheating before welding in order to eliminate the stress after welding processing.

34CrNiMo6 Steel Stock in Warehouse

2: 34CrNiMo6 Quality Standard

34CrNiMo6 steel according to EN 10083-3.

3: 34CrNiMo6 Steel Equivalent

Country | Germany | USA |

Standard | EN 10083-3 | ASTM A29 |

Grade | 34CrNiMo6/1.6582 | 4337 |

4: 34CrNiMo6 Steel Chemical Composition

Grade | C | Si | Mn | P | S | Cr | Mo | Ni |

4337 | 0.30-0.40 | 0.20-0.35 | 0.60-0.80 | 0.035 | 0.04 | 0.70-0.90 | 0.20-0.30 | 1.65-2.00 |

34CrNiMo6 | 0.30-0.38 | 0.40 | 0.50-0.80 | 0.025 | 0.035 | 1.30-1.70 | 0.15-0.30 | 1.30-1.70 |

5: 34CrNiMo6 Steel Mechanical Properties

The mechanical properties mainly include tensile strength, yield strength, elongation, area or reduction, hardness, impact value, non-metalic inclusion etc. Different heat treatment, the mechanical properties will be different, such as normalized, tempered, QT. If you want to know the properties, kindly contact the salesman.

6: Qilu Company Profile

Hunan Qilu was engaged in steel exporting since 2008 year, the former was the sales company for Qilu Special Steel co.,ltd which was founded in 1986 year. Now Hunan Qilu Metal is one of most professional steel manufacturer and exporter in China. We already exported steel material to Germany, UK, Ireland, Greece, Italy, Poland,Belgium, Estonia, Latvia, Spain, France, Netherlands, Portugal, Czech republic, Finland, Russia, Belarus, Canada, Mexico, Brazil, Chile, Colombia, Peru, Argentina, Venezuela, Thailand, Indonesia, Vietnam, Singapore, Malaysia, Philippines, UAE, South Africa, Zambia, Australia etc.

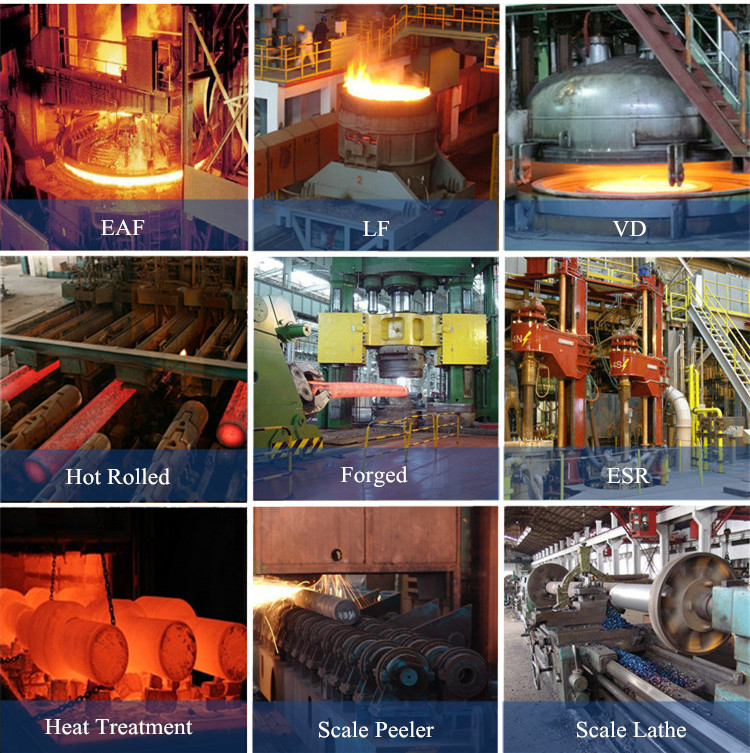

7: Production Equipment

The company owns advanced special steel smelting facilities and forging processing equipment, the main steel-making equipment include 2 set of 50t and 25t ultra-high power electric arc furnaces, 2 set of 60t and 30t LF refining furnaces, 2 set of 60t and 30t vacuum degassing refining furnace. 4 sets of 1-20t electroslag re-melting furnaces.

The main forging equipment mainly include:3 sets of 3t 5t and 8t electro-hydraulic hammers, 3 sets of high-speed forging units of 1600t, 2000t and 4500t respectively.

8: Our Company Certificate

We already passed ISO 9000 : 2015 certificate of quality system, and we could supply steel forging material with all kinds of Classification Society Certification, such as ABS, ,DNV, BV, CCS etc. We also supplied steel material to oil industry with API certificate, such as API20B, API6A etc.

9: Stock&Warehouse

Besides forging material, we also supply hot rolled material from Dongbei special steel, Tiangong, Changcheng special steel, Lihuai Special Steel, Laisteel, Juneng steel, Yongsteel, Xinxin steel, Shijiazhuang steel etc. We have two warehouses for hot rolled material. Further processing such as heating treatment, rough machining and milled are also provided by us.

10: 34CrNiMo6 Steel Overviews

Size | Round | Dia 6-1200mm |

Plate/Flat/Block | Thickness | |

Width | ||

Heat treatment | Normalized ; Annealed ; Quenched ; Tempered | |

Surface condition | Black; Peeled; Polished; Machined; Grinded; Turned; Milled | |

Delivery condition | Forged; Hot rolled; Cold drawn | |

Test | Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. | |

Payment terms | T/T;L/C;/Money gram/ Paypal | |

Trade terms | FOB; CIF; C&F; etc.. | |

Delivery time | 30-45 days | |

11: 34CrNiMo6 Steel Tolerance

Diameter(mm) | Tolerance | ||

Forged Steel Round Bar | 80-600 | Black Surface:0~+5 | Rough Machined or Turned:0~+3 |

650-1200 | Black Surface:0~+15 | Rough Machined or Turned:0~+3 | |

Hot Rolled Steel Round Bar | 16-310 | Black Surface:0~+1 | Peeled:H11 |

Cold Drawn Steel Round Bar | 6-100 | Black Surface:H11 | Peeled:H11 |

12: Packing& Delivery

For the delivery, we will choose LCL, FCL and Bulk carrier according to order quantity. Usually if the quantity is less than 10tons, we will recommend LCL. If the quantity is more than 100tons, we will recommend bulk carrier. Usually FCL will be the most common for delivery.

In order to better ensure the safety of your goods, we will provide professional, environmentally friendly, convenient and efficient packaging services. Such as pallet, wooden box, package with woven bag etc.

13: 34CrNiMo6 Steel Heat Treatment

Quenched and Tempered (Q+T) of 34CrNiMo6 Steel

Heat 34CrNiMo6 round steel slowly to the temperature of 850°C;

Soak at this hardening temperature quench in oil;

Temper as soon as 34CrNiMo6 steels reach room temperature.

Heat uniformly to the suitable temperature;

Withdraw from the furnace and cool in the air.

The usual tempering temperature is 600°C which depending on the actual requirements.

Forging

Hot forming temperature: 1100-900oC.

Machinability

Machining is best done with this 1.6582 alloy steel in the annealed or normalized and tempered condition. It can be machined by all conventional methods.

Welding

The alloy materials can be fusion or resistance welded. Preheat and post heat weld procedures should be followed when welding this alloy by established methods.

14: 34CrNiMo6 Steel Application

34CrNiMo6 are used for heavy machinery axle,turbine shaft blade, high load of transmission parts, fasteners, crank shafts, gears, as well as heavily loaded parts for motor construction etc.

15: Delivery Condition

For hot forged or hot rolled bar, usually the delivery condition is hot forged or rolled, annealed or QT, black surface or rough turned.

For hot forged plate, usually the delivery condition is hot forged, annealed or QT, milled surface.

For hot rolled plate, usually the delivery condition is hot rolled, annealed or QT, black surface.